Some Known Details About Sheroz Earthworks

Some Known Details About Sheroz Earthworks

Blog Article

Sheroz Earthworks - Questions

Table of ContentsThe Best Guide To Sheroz EarthworksAn Unbiased View of Sheroz EarthworksSheroz Earthworks - TruthsSheroz Earthworks Fundamentals ExplainedSome Known Incorrect Statements About Sheroz Earthworks

For any earthwork professional, it is essential to do collaborate with top quality, precision, and on schedule. Utilizing maker control in job machines allows optimizing the various phases in the earthwork process, from planning to the upkeep stage - trimble repair parts. The equipment control system assists the machine operator in attaining the target aircraft promptly and quickly

The equipment control system guides the operator with centimeter precision. With Xsite PRO 3D, you'll constantly recognize specifically how much to cut or fill. Your neighborhood Xsite technical assistance can direct you and assist with any troubles without visiting the site. Remote support saves money and time, as it minimizes downtime in jobsites.

The 6-Second Trick For Sheroz Earthworks

Our system's elements are carefully made to withstand the rough problems of building and construction sites. Contrast of the very same job executed using machine control versus the traditional method discloses that, on average, the traditional technique needs 50% even more time to achieve the same job as the technology-assisted method.

Enter the Xsite equipment control system; it's here to offer you with a significant benefit when working with earthmoving machinery. Discover exactly how Xsite Equipment Control can boost your performance and make certain work security! Xsite Device Control systems can be mounted to any kind of excavator from mini excavators to large mining excavators.

How does device control job? In 2D systems, the maker is furnished with adjusted disposition sensing units.

The system is extremely simple to discover the basics can be shown in under one hour of training. With Xsite you do not have to stress over learning all the ideas and trick simultaneously. Added training and directions are always available over remote support when needed. Contact your neighborhood Xsite dealership to find out even more! Exactly how does the remote assistance work? A cordless net link makes it possible to establish a remote connection in between the machine control system and the service.

The 6-Minute Rule for Sheroz Earthworks

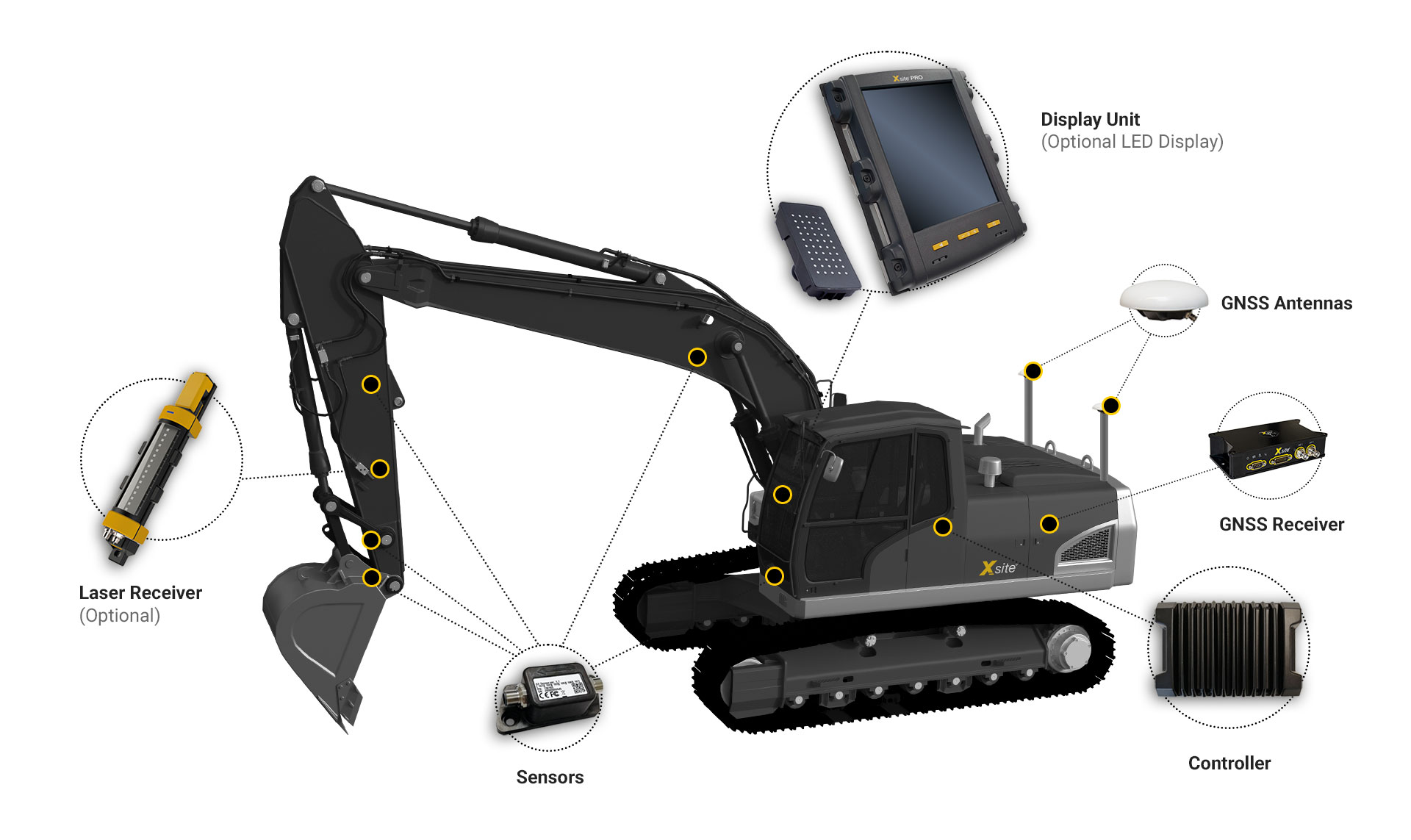

What kind of information styles Xsite systems assistance? Xsite Device Control systems sustain open standard documents layouts, making it possible for smooth details circulation from one system to an additional. Sustained data formats: 2D-Maps: DXF Factor data: DXF, XML, GT, CSV, KOF, PXY Geometry lines: VGP, SBG, XML, Anpakke Surface Models: DXF, XML What parts are set up on my maker? Relying on your choice of system (with or without positioning, i.e - topcon laser levels., 2D or 3D), your machine is outfitted with disposition sensors, a controller unit, and a Extra resources display/operating panel.

Numerous software and hardware remedies exist to help establish a maker's current placement on the earth and compare it with a wanted style surfaceand building drivers can do more to utilize the benefits. Equipment control is using different placing sensing units and a display screen to provide the driver with a reference between the placement of the container or blade and the target grade.

Depending upon the setup, equipment control systems can supply the operator with an easy aesthetic overview to bucket or blade placement, or can automatically relocate the blade to grade by speaking with the device's hydraulics - https://www.domestika.org/en/floydoverbeck4500. There are maker control systems readily available for simply about any type of equipment: graders, dozers, excavators, dirt and asphalt compactors, scrapes, leaners, crushing makers, and pavers

Sheroz Earthworks Can Be Fun For Everyone

Some benefits include reduced rework, boosted job effectiveness, and reduced checking costs. Maker control can additionally assist boost productivity and reduce general costs. This innovation is changing the means the building and construction market functions. Building equipment without equipment control will certainly become a distant memory and the advantages gained from it will certainly be various.

Trimble maker control systems supply a myriad of benefits to anybody that makes use of earthwork equipment and, at EarthCalc, we can supply you with 3D files for your maker control-enable tools. Unsure if device control is worth the expense? Take into consideration the complying with reasons that you require to consider this choice.

Making use of general practitioner aligned with your 3D design data, these systems essentially ensure that you will certainly get rid of or position the proper quantity of product at the construction site. On many building and construction sites, revamp is an usual and discouraging reality, yet with Trimble equipment control, you can remove the requirement for rework.

Some Of Sheroz Earthworks

Typically, with Trimble equipment control, you can get rid of excess equipment at a particular work website. A job that could have required the use of three or 4 pieces of excavating tools now may need just 2 pieces of tools to complete the same job in less time. This permits you to relocate your tools to one more work website and take care of several work at once.

Report this page